Benefits of Using CNC Technology for Fabrication

The Numerous Benefits Of Using CNC Technology For Fabrication

The Fabricators

Numerous fabricators have shared how their investment in machinery and technology has increased their performance and benefited their businesses. CNC machines enable a faster, more efficient completion of detailed work. The basic fabrication using granite blades and the quartzite blade have changes as technology progresses.

The New Tools

New CNC tools have been designed for trendier materials including Neolith, Lapitek and Dekton. These materials differ from quartz, and their parameters require a different type of tooling. Our conventional techniques are ineffective due to the hardness of the materials. The tension must be released before fabrication.

The High-Speed Finger Bit

We use this bit for optimal finish, speed and performance, and a constant contact with the stone is ensured. As with most granite tools, we use this bit for all types of granite, quartz and engineered stones. The rate of speed per minutes is 18”-24”, and the bit has a 600’ life range. There are numerous sizes available.

The Terminator Zoom

These profiles were created with precision, the tool labels are pre-measured, and set-ups are simpler with more accuracy. We have elevated out production to 100-250 in/min, and the fit is a standard quality. We keep our inventory stocked, and complete unique jobs with custom shapes.

The Leatherhead Mini

We can adapt this mini to all our 35mm tool holders. We use it on Electro-Spindle and belt driven machines. The compact design enables us to use it for most standard tool racks, so our process for brushing can be automated.

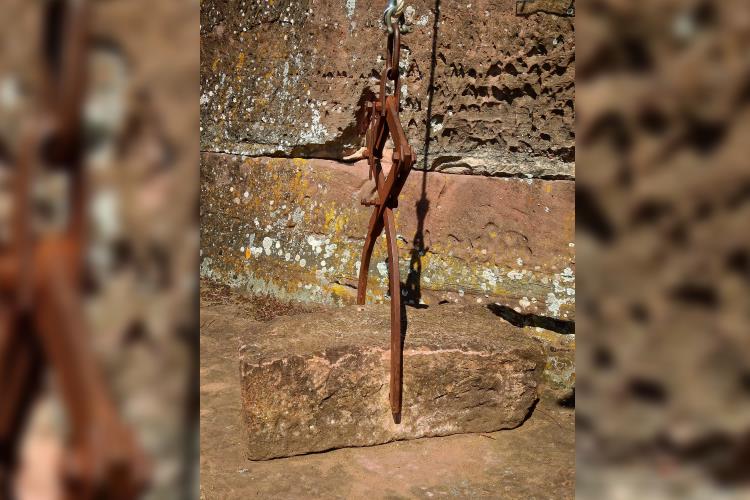

The CNC Finger Bit

This bit is great for stones such as granite, and we have seen extraordinary results during rough conditions for fabricating. This is a Cyclone Seven-Finger bit we use to quickly cut through hard materials. The diameter is smaller, and we find the seven segments useful.

The V Style Power Edge Z Wheel

The new segment enables us to remove more material while machining quicker. The amperage draw is lower, the finish more consistent, and the tool has a long life.

The Right CNC Tooling

Using the right equipment for our stone fabrication is important. CNC tooling products come from three excellent manufacturers. Our requirements are satisfied with the distinct technical and physical characteristics of each product. We considered out purchases carefully, and decided the benefits were worth the payments.

A Better Product

The tools enable us to provide both detailed and cheap work both efficient and profitable. We did our research and based our choices on reputation, quality and service. We ensured the specifics of our standards were met. The quality of the granite tools is excellent, and our sink holes and edging have improved. The time necessary for more difficult jobs has decreased including difficult shapes and radius jobs.

Hand Shaping

Hand shaping with a quartzite blade or granite blades is not as accurate or efficient as the newer CNC technology. Our flow and template capacity have more capabilities due to technology. We have never once regretted our investment in CNC. We don’t see any disadvantages, and have all learned how to manually fabricate. If a machine is down, we can continue working by hand.

Full Digital

Our shop is only partially digital, but we use CNC for most of our edging and sink holes. This is very advantageous for lazy-susan or curvy tops. We are considering a full digital shop before much more time has passed. Some of the seminars we attended made us realize how much time we could save, and how much would be gained in accuracy and quality.

The Benefits of CNC Technology

We never have to turn down works because of bottlenecks in production anymore. As we started purchasing different machines, they quickly became our best assets. We are making more money without any additional stress, and our quality has improved. CNC has given us the ability to grow, become more efficient, take on more jobs, and produce work of a much higher quality.